At Eco H2O, we believe in clear, honest advice – especially when it comes to technologies that many homeowners are hearing about for the first time.

As we move toward a lower-carbon future, Air Source Heat Pumps (ASHPs) are quickly becoming the go-to alternative to traditional gas boilers – and for good reason. But what exactly are they, and how do they work?

In this article, we’ll break down the technical components, heat transfer principles and installation factors that make air source heat pumps a smart, sustainable choice for modern homes and commercial buildings.

The Science Behind Air Source Heat Pumps

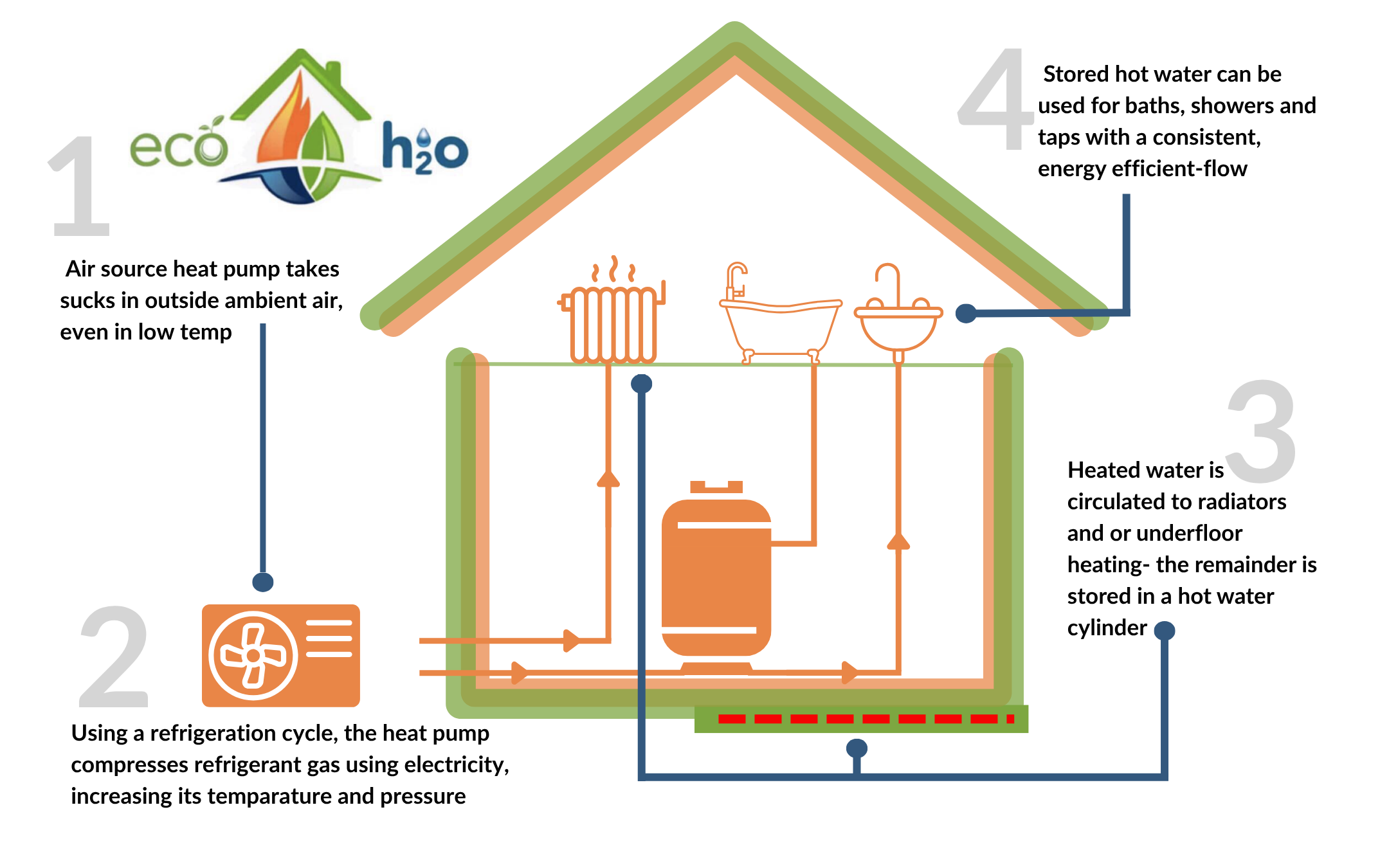

Air source heat pumps operate on the same basic thermodynamic principles as your fridge – but in reverse. They extract heat energy from the outside air, compress it and transfer it into your home to heat radiators, underfloor heating or hot water cylinders.

The system uses vapour-compression refrigeration cycle, made up of four key stages:

1. Evaporation – Heat Extraction from Ambient Air

The outdoor unit houses a heat exchanger coil (evaporator) filled with a low-boiling point refrigerant (often R32 or R410A). As the refrigerant passes through this coil, it absorbs heat from the outside air – even when air temperatures drop below freezing.

- Key point: Even cold air contains thermal energy. Heat pumps can extract usable energy from air as cold as -15°C or lower.

2. Compression – Boosting the Temperature

The now-warmed, low pressure refrigerant gas enters a compressor which significantly increases both pressure and temperature. This is where the real heat “gain” happens.

- Compressor types: Scroll compressors are common for domestic ASHPs due to their efficiency and low noise levels.

3. Condensation – Heat Delivery to the Property

The high-temperature refrigerant moves to the indoor unit (or hydrobox), where it passes through a condenser coil. Here, it releases heat into the water system used for space heating or domestic hot water.

- The refrigerant condenses back into a liquid during this phase.

4. Expansion – Restarting the Cycle

The refrigerant, now a high-pressure liquid, passes through an expansion valve, which drops the pressure and temperature, resetting it to absorb more ambient heat. The cycle then repeats continuously.

Key Components of an ASHP system

- Outdoor Unit: Contains an evaporator coil, fan and compressor

- Indoor Unit (Hydrobox): Transfers heat to the home’s heating system

- Refrigerant Circuit: Closed-loop system facilitating heat transfer

- Expansion Valve: Regulates refrigerant flow and pressure

- Buffer Tank/Hot Water Cylinder: Stores hot water for taps or space heating

- Controller/Thermostat: Optimises settings for efficiency

Performance: The Coefficient of Performance (COP)

The COP is a ratio that measures the efficiency of a heat pump. A typical ASHP has a COP of 3 to 4, meaning it produces 3-4 kW of heat for every 1kW of electricity it consumes.

- Translation: You’re getting 300-400% efficiency compared to a standard electric heater.

- Tip: Real-world performance varies with outdoor temperature and the property’s insulation.

Is My Home Suitable for an Air Source Heat Pump?

While ASHPs can be installed in most homes, they’re most efficient when paired with:

- Underfloor heating or low-temperature radiators

- Good insulation levels (EPC rating of C or above is ideal)

- Space for the outdoor unit with god airflow and minimal obstruction

Benefits of ASHPs

- Lower running costs (especially with off-peak tarriffs)

- Reduced carbon emissions

- Eligible for grants/incentives (e.g Boiler Upgrade Scheme in Scotland)

- Can both heat and cool in some configurations

- Minimal maintenance compared to fossil-fuel systems

What we offer at Eco H2O

At Eco H2O we provide a full in-house design, installation and commissioning of air and ground source renewable technologies. We are MCS-accredited on the installation of renewable energy products. We are also accredited with manufacturers ie. Mitsubishi, Vaillant and Grant UK heating products.

Want to know more?

If you’re considering a heat pump for your home or business, our qualified engineers can assess your property and provide tailored recommendations – no pressure, just honest advice.